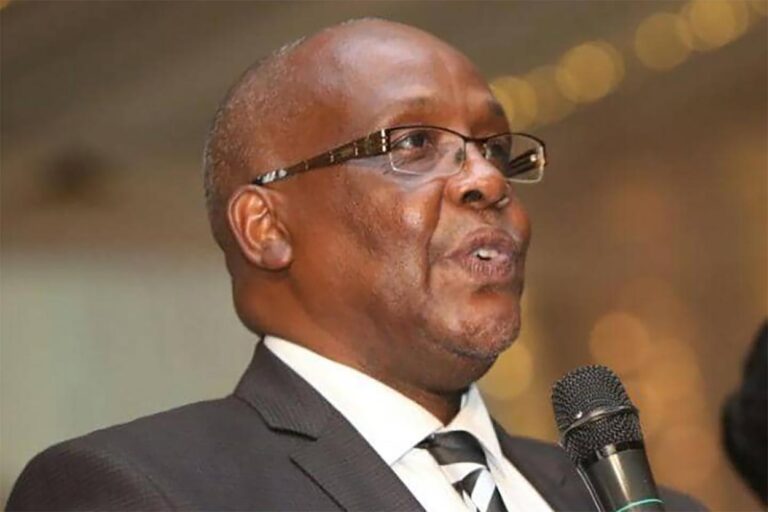

Dr Ezra Rubanda Muhumuza, the UMA executive director (M) charting with Vincent Ernest Nguimbi, the Director for East Africa and Francophone at the Kaizen Institute during the MOU signing ceremony

HABARI DAILY I Kampala, Uganda I Uganda Manufacturers Association (UMA) has signed a partnership agreement with Kaizen Institute, to boost the business stature of its members.

A pioneer in the field of Continuous Improvement and Lean Management, the Kaizen Institute was founded in 1985 by Masaaki Imai. They currently have a presence in 60 countries worldwide, where they offer training in the above fields.

The partnership seeks to make UMA member companies more competitive, and gain access to support research and literature on good governance, which guarantees increased production.

According to Vincent Ernest Nguimbi, a director for East Africa and Francophone at Kaizen Institute, the major areas they will focus on during the five-year partnership with UMA include improving excellence of companies, streamlining operations and enforcing ESG principles.

“Through research, the institute will enable UMA members to access experts who will train them on business support and how innovation can turn their businesses around,” he said, after the signing ceremony which was held at the UMA headquarters in Lugogo, Kampala.

He said through the Kaizen, UMA members will be taught to adopt continuous learning to ensure they beat competition that is rampant in today’s business world.

Dr Ezra Rubanda Muhumuza, the UMA executive director, the Kaizen training will boost their member’s corporate image and enable them compete globally.

“This will boost both our market access and presence,” he said, adding that the training will be conducted at three levels.

“One will be through the general member’s association, through sector platforms specially with focus on how to enforce healthy competition amongst fellow players, and for individual companies with special challenges affecting their output.”

He further noted that the end goal of the training will be profits for the company, reduced cost of operation, increased employment opportunities and well-trained and a maintained workforce.

“Once they have gone through the training, our members will be in a position to assume maximum production capacity and production of good quality products.